Your questions answered by Car Insulation UK

"How to fit car soundproofing material in my car?"

"Fitting car or van soundproofing advice?"

"Help fitting car soundproofing materials in my car or a van!"

"Installing car soundproofing in van or a car" "Installing car or van sound insulation"

4) Creating a template before cutting and fitting car or van soundproofing material. There are several ways to make a template or pattern when soundproofing your car or van.

If you decide to make a template rather than start cutting soundproofing material straight away you will usually save money when soundproofing your car or a van as you should not have to re-cut soundproofing parts and will be able to fine tune your pattern. Also it is usually time saving as most areas of the vehicle are usually symmetrically opposite so this pattern or template can be flipped over to make the part for the other side of the vehicle.

For example if you are cutting the LH car door soundproofing the RH car door soundproofing is usually opposite. Which material should you use for a pattern when fitting car soundproofing? Some customers use cardboard or paper and others use old sheets or dust sheets. Whichever material you decide to use the process is fairly similar when creating a template to soundproof your car or a van.

Please note that if you are planning fitting soundproofing material over 15mm try to account for the thickness when creating your soundproofing template, or use a material that is as close to the thickness.

a) Take approximate measurements of the area your are looking to fit soundproofing to and find a piece of material or card large enough for the area of the car you are looking to soundproof. (ensure the material is pliable/flexible)

b) Cut the piece 100mm over sized and roughly to the correct shape whilst accounting for any raised areas or depressions in the soundproofing application.

c) Find the "best fit" along one edge of the soundproofing template and secure this in place with either piercing the material with studs on the vehicle (you usually find these on tunnel, floor and wheel arch soundproofing applications) or some adhesive tape. Try to use the highest point as the starting edge where possible and hang the soundproofing template.

d) Start with any holes that are required in the material, do not add holes where they are not absolutely necessary as this can reduce the performance achieved by the car soundproofing material.

e) Next mark on the template with pencil or marker any areas where you need to increase the templates size and any areas which you need to reduce. Carefully remove the template and trim where necessary or add pieces and fix with tape where it is required to increase the size.

g) If there are any changes in direction of the car body by more than 30 degrees. Add perforation lines by adding 20mm cut lines and 20mm gaps this will help the material to take the shape of the body work.

j) Remove and re-fit to ensure you are happy with the car soundproofing template coverage, loosely fit components over the top of the template to ensure they will after you add the soundproofing. Cut away any area if you are using non-compressible soundproofing material and it clashes with the car components.

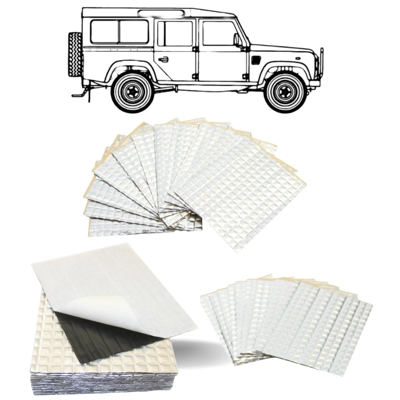

5) Cutting your car or a van soundproofing materials to shape. All of our car or a van soundproofing materials are easy to cut with scissors or a sharp knife.

If you are using tools please use safe working practices and seek health and safety advice if required.

If you are installing car or a van soundproofing materials which are Car sound absorption materials: as a simple guide, the performance is directly related to the area of soundproofing material installed. Also as a rule of thumb the thicker the material, the lower the acoustic frequency it is able to absorb. Fiber thickness in acoustic materials and acoustic material airflow characteristics also affect this considerably.

If you are fitting car soundproofing products which are heavy matting Transmission loss materials: you usually achieve the best results with the best coverage of soundproofing and least holes and gaps in the soundproofing material. Car soundproofing coverage is key and for optimum results combine a heavy matting soundproofing material with a car sound absorbing material. Adhere the sound absorbing material to the body panel first and add the heavy matting soundproofing material in place.

If you are installing car or a van soundproofing products which are Anti-vibration materials: usually 100% soundproofing material coverage is not always necessary and installing 50% soundproofing material coverage will usually provide the desired affect. The key is ensuring the soundproofing materials are fully bonded and installed correctly by using pressure and assisting the soundproofing material into the form prior to applying pressure to the soundproofing material.

Prior to cutting your soundproofing material either make a soundproofing template / pattern (see above) or measure the dimensions required twice ensuring that you account for depressions and form in the body panels you are soundproofing.

-

Cut the soundproofing material to shape including any holes and perforations to aid installation of the car soundproofing.

-

Offer the car soundproofing part into place and offer up any components which fit on top of the soundproofing part you have just cut. Check that the material will not "hold off" any components and ensure that any temperature sensitive components are not covered. Trim the part if necessary.

-

Remove protective film if the soundproofing material has adhesive backing and install car soundproofing in place. Use studs and clips where possible or alternatively use high quality automotive grade double sided tape to hold the material in place. (ensure material is safely bonded or fixed in place prior to fitting components back in place)